Improving Sustainability in Alkyd Wood Coatings with Linseed Oil and High-Performance Catalysts

September 26, 2023 | Blog

In recent years, there has been an increased demand for improving the sustainability of coatings for wood. Replacing oils and driers in these coatings is one way to improve sustainability. However, when replacing current materials with more sustainable alternatives, coating formulators may be concerned about negatively impacting performance when adopting these options. Utilizing a combination of bio-based linseed oil with Borchi® cobalt-free high-performance catalysts (HPCs) has been proven to enhance performance properties like scratch resistance and water resistance while improving the sustainability of wood coatings.

The Increasing Demand for Sustainable Wood Coatings

In today’s wood coating market, both the Do-it-Yourself (DIY) and professional decorative segments are actively seeking sustainable coating options for many wood surfaces. Traditional oils used in wood coatings are typically derived from fossil raw materials which often contain high levels of Volatile Organic Compound (VOC) content. These paints pose environmental and health risks that require GHS pictograms and have a strong odor.

The drier packages used in alkyd wood coatings also raise concerns as they typically contain cobalt, which is facing toxicity concerns due to exposure risks in coating applications. This has prompted various regions to consider restrictions and reclassifications for cobalt siccatives used in coatings. Reclassification may require GHS pictograms on coatings with these driers.

Meeting the Demand for Sustainable Coatings

Fortunately for coating formulators, 100% natural oils for wood and cobalt-free curing additives for coatings are already available. These alternatives not only offer improved sustainability but, in many cases, even elevate performance.

Natural Oil for Wood

Compared to solvent-based and high-solids oils, solvent-free and very high-solids natural oils exhibit excellent sustainability properties. These bio-based oils are free of volatile organic compounds and do not require hazard pictograms. Moreover, they also have little to no odor. A prime example of an efficient natural oil is linseed oil.

Benefits of Linseed Oil in Coatings

Linseed oil, derived from the dried seeds of the flax plant, is a bio-based and VOC-free oil suitable for various coatings for wood. It boasts several advantages, including excellent adhesion, color, and elasticity. Furthermore, it effectively safeguards against changes in humidity and penetrates deep into the wood.

Challenges of Linseed Oil in Coatings

Although linseed oil on wood has many advantages, it also presents certain performance challenges in many applications. For instance, it exhibits long through-dry times, limited pot life in 2K systems, and wrinkling at high film builds. Additionally, linseed oil can result in coatings with high Gardner color numbers. Using the appropriate coating additives to overcome these challenges is crucial while ensuring sustainability remains uncompromised.

Cobalt Drier Alternative Options

Cobalt-Free High-Performance Catalysts (HPCs)

Borchi® OXY-Coat 1310 high-performance catalyst curing additive serves as an effective cobalt drier alternative for wood coatings, particularly when used with linseed oil-based alkyd resins. This HPC is a patented organometallic ligand technology that is free of carcinogenic, mutagenic, or reprotoxic materials. It is also alkylphenol ethoxylate (APEO)-free, REACH compliant, and globally registered. By utilizing HPCs, formulators can achieve excellent performance, countering the challenges associated with raw linseed oil.

Manganese Driers

As formulators shift away from cobalt-based driers, some may consider using manganese driers in their place. However, manganese driers tend to cause discoloration and darker shades.

Achieving Performance – HPCs vs. Manganese Driers

HPCs have been extensively tested against manganese driers in various linseed oil-based wood coating formulations. These include 1K wood oil, 2K dual cure parquet oil, and waterborne acrylic hybrid wood stain formulations. The results clearly demonstrate that HPC formulations offer longer pot life, lower Gardner color, improved wrinkling resistance, enhanced chemical resistance, and faster drying times compared to manganese drier formulations.

Dry Time Performance

The dry time performance of the HPC in the 1K wood oil formulation surpassed the manganese dry time.

Manganese driers resulted in higher dry times and loss of dry compared to HPC in the 1K wood care oil formulation. Borchi OXY-Coat 1310 HPC provided the most efficient dry times and loss of dry in this formulation.

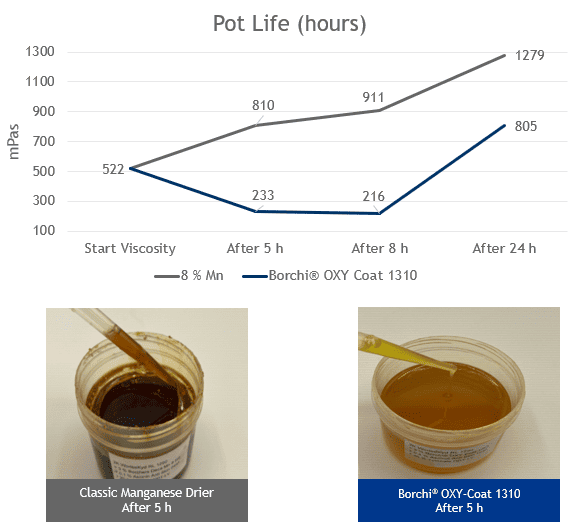

Pot Life Performance

HPC increased pot life in the 2K dual cure parquet oil formulation with linseed natural oils for wood.

Borchi OXY-Coat 1310 helped the coating remain less viscous over time in storage compared to a classic manganese drier in the 2K dual cure parquet oil.

Wrinkle Performance

Coatings for wood tend to wrinkle when applied too thick. The HPC prevented wrinkling from occurring better than manganese in the 1K wood care oil formulation.

The coating with the manganese drier shows more wrinkling compared to Borchi OXY-Coat 1310 in the 1K wood care oil formulation on oak, results shown below at 10x magnification.

Gardner Color Performance

In wood coatings, a higher Gardner color number results in a darker color, which negatively impacts color in transparent wood coatings. As manganese is naturally dark, this drier is not an ideal cobalt replacement in wood coatings when it comes to color performance. In the 1K wood care oil formulation, the HPC helped maintain lighter color in wood coatings.

Borchi OXY-Coat 1310 provided better color better than manganese driers in the 1K wood care oil formulation.

Chemical and Stain Resistance

When substances spill onto wood surfaces, the type of coating applied can affect the impact wood stains will have on a surface over time. In the waterborne hybrid wood stain formulation, the HPC demonstrated excellent chemical resistance against common household stains. The stains tested include ketchup, coffee, ammonia water, and red wine. The HPC formulation exhibited improved chemical resistance against ammonia water when compared to manganese.

HPCs show stronger chemical resistance against common household stains compared to a manganese drier in the waterborne hybrid wood stain formulation with an acrylic dispersion. Borchi OXY-Coat 1310 allowed for little change in surface appearance when ammonia water was spilled.

For more information on the wood coating formulations tested, please download our webinar on utilizing HPCs in wood coatings.

Conclusion: Sustainability Can be Improved without Sacrificing Performance in Wood Coatings

With the demand continuing to increase for bio-based materials, 100% natural linseed oil is a good choice for wood coatings. While linseed oil alkyd resins improve sustainability in coatings, the common use of cobalt driers with alkyds falls short in this aspect. However, by utilizing Borchi HPC driers as alternatives for cobalt or manganese driers, sustainability can be improved without compromising performance.

As a sustainability-focused organization, Milliken & Company is committed to developing solutions that provide a positive impact for generations to come. As a part of Milliken, the Borchers brand aims to provide coating additives that are safer for the environment, which further enhances the sustainability of our customer’s products.

The development of coating additives like Borchi HPCs is an example of our brand moving toward safer solutions for customers. Cobalt-free HPCs eliminate the use of certain chemicals of concern without sacrificing performance.

Explore our website to learn more about Borchi HPCs and other additives for wood coatings.

You can also visit our Contact Us page to connect with our team.