Dispersing Agent for Carbon Black Pigments and Difficult to Disperse Organic Pigments

Borchi® Gen 0451 is a high molecular weight non-ionic and VOC-free dispersing agent for carbon black pigments. This dispersant additive for paints and coatings provides better jetness in carbon black pigment dispersions and also improves color development in difficult-to-disperse organic pigments in both water- and solvent-based systems. It provides shorter grind times, higher gloss performance, high jetness, low viscosity dispersions, and long-term viscosity.

Carbon Black Pigment Characteristics

Carbon black pigments are typically made from the charring of organic substances. They have notoriously low surface charge and wetting characteristics. This makes them difficult to disperse in either organic or aqueous mediums.

Much carbon black is used in tire and rubber applications to provide enhanced mechanical and wear properties, as well as rubber’s characteristic black color. However, these pigments are also ideal for use in automotive, industrial, and protective and marine coating applications where they provide great color and hide, and can ultimately improve coating performance. They can also be used in printing inks.

While carbon black pigments alone have excellent concealing ability, dispersants like Borchi® Gen 0451 take their dark color to the next level. This dispersant provides high quality color in coatings and printing inks.

Benefits of Carbon Black Dispersants

As a carbon black dispersant, Borchi® Gen 0451 is known for providing high jetness, or an enhanced jet black color. High jetness is achieved through thorough dispersion of pigments during grind and by providing shelf stability through both electrostatic and steric stabilization of the pigment particles to prevent reagglomeration. Borchi® Gen 0451 also helps coatings achieve better gloss performance.

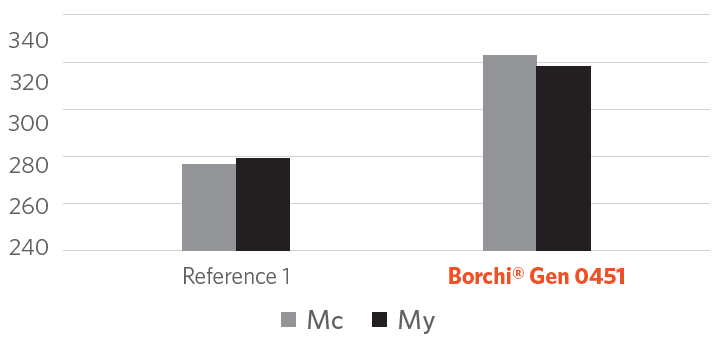

Higher Jetness (Mc) and Hue Dependent Blackness (My)

Borchi® Gen 0451 shows higher jetness and blackness in a 2K polyurethane solvent-based coating

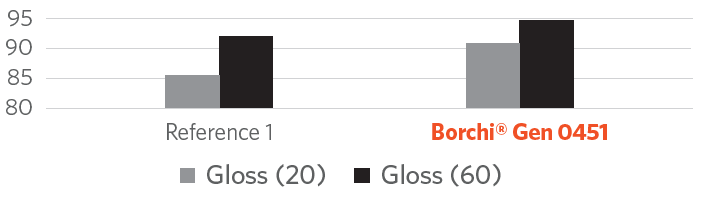

20° & 60° Gloss

Borchi® Gen 0451 provides the highest gloss performance for formulations with carbon black pigments. Higher gloss, or sheen, indicates better durability in coatings with carbon black

Benefits of Organic Pigment Dispersants

Organic pigments are difficult to disperse due to their small particle sizes and low surface charge. Dispersing agents like Borchi® Gen 0451 are engineered to efficiently disperse these pigments, which ultimately results in enhanced color.

Borchi® Gen 0451 is engineered to maximize the interaction and subsequent wetting of difficult to disperse, high surface area organic pigments. Optimized pigment wetting with dispersants will produce smaller particle size dispersions of organic and carbon black pigments with lower viscosity and improved dispersion stability. This is how the dispersant ultimately provides better color development for coatings.

Similar Dispersing Agents

Other organic pigment and carbon black dispersants from Borchers include Borchi® Gen 0851 for water-based coatings. Like Borchi® Gen 0451, this dispersing agent effectively disperses difficult to disperse organic pigments and carbon black pigments for enhanced color development.

Applications

Borchi® Gen 0451 is ideal for use in automotive, industrial, protective and marine, and decorative coating applications. It can also be used in printing inks.

Physical Characteristics

Appearance Liquid, yellow-orange Non-volatile content 100 % pH 8 – 10 (aqueous

solution 10 %)Density 1.09 – 1.15 g/cm3 Viscosity Max. 30,000 mPa.s Solvent(s) NA Features

- Specifically designed as a carbon black dispersant

- Also works for difficult to disperse organic pigments

- Low viscosity dispersions

- High transparency with organic pigments

- Long-term dispersion stability

- Compatible with a wide range of resin systems

Applications

- Coatings

- Automotive

- Industrial

- Protective and Marine

- Decorative

- Printing inks

- Coatings

Dosage

Depending on the pigment grade, the recommended dosage is

- Organic pigments: 20 – 35 %

- Medium black: 40 – 50 %

- High jetness carbon black: 70 – 100 %

The exact dosage should be experimentally determined through a ladder study. Borchi® Gen 0451 should be added to the mill base before adding the pigment.

Storage

Protect from the effects of weather and store at temperatures between 15 and 30 °C. Turbidity and flocculation may occur if Borchi® Gen 0451 is exposed to temperatures below 15 °C. This effect is reversible and does not affect its potency.

Warm the material to room temperature and mix well before using. If its viscosity has also increased and it is difficult to handle the material must be heated to 50 °C to return the viscosity to normal. Once opened, containers should be resealed immediately after each removal of the product.

Safety

Please refer to our safety data sheet for information relating to product safety.

- Availability : All , Americas , Asia , EMEA

- Media : Solvent-based , Water-based

Registration :

For chemical inventory status, please review section 15 of the current SDS.

Click here to access the SDS portal.

For additional regulatory information, please contact [email protected].

Wetting and Dispersing Products

Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »